Services

From the initial idea to a successful project.

We accompany our customers along all phases of a project until its successful start-up and beyond. Our services include:

- Feasibility studies

- User requirement specification

- Functional specification

- Installation

- Commissioning

- After-sales service

We also handle projects as general contractors.

In parallel with the installation of the system, we train the operators and administrators of the various customer teams. During the training, we listen very carefully to the system users in order to understand the specifics of the application and be able to implement them successfully in the system. This makes for high user acceptance.

Our customers can rely on our professional service also after completion of the project and commissioning of the system. After-sales service by our experienced technicians, including 24/7 on-call service and remote maintenance, are standard components of our customer support.

Order-specific user software

Numerous tasks in the metals industry are too complex to be efficiently handled by standard software solutions.

For special production processes or extraordinary operating procedures, order-specific software programming is needed. Here we bring to bear our profound knowhow in warehouse and transport logistics and our in-depth understanding of the processes in the metals industry.

An example is the coil discharge in a hot strip mill:

- The process management system implemented by 3tn manages all coil handling processes downstream of the hot strip mill - the removal of the coil from the recoiler and all other process steps down to the delivery of the coil at the hot coil store. For that project, we implemented specific rule books for sampling, coil tying and coil weighing. Based on these rules and the characteristics of each coil, the system automatically decides which coil handling route will be taken to ensure, for example, that the coil is properly coiled and marked.

- The system also determines whether a coil has to be sampled and, if so, what kind of tests would have to be performed. In this way, the system automatically generates the input data for downstream units, such as the tying and marking machines and the inspection line.

- That project is an example of how we bring to bear our expertise in rule-based systems. Thanks to our rule books the process of entering the coil data has become a largely automated process, relieving the operators from the need to handle each coil specifically.

FAQ Frequently Asked Questions

Storing slabs, coils and plates as efficiently as possible has always been a challenging endeavor in the steel and aluminum industries.

Product storage and handling are much more complicated than in other sectors or, for example, in high-bay stores. Slabs and coils – often of different sizes – have to be stacked on top of each other. This requires numerous parameters to be observed, for instance, the condition of the product surface and the product weights, all of which determine the forces acting on the stored items and on the equipment and the sinking depths.

Additionally, various restrictions have to be taken into account in order to find the best suited storage position for each individual stored product.

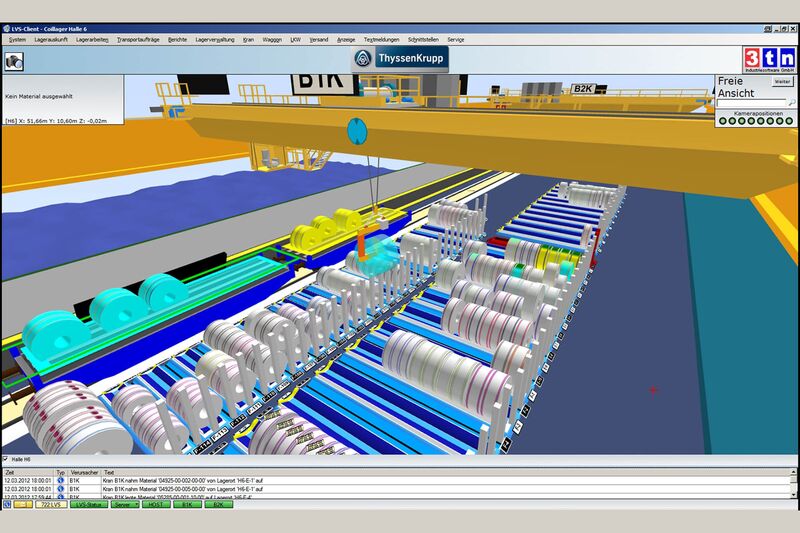

We have developed TWMS/metals specifically for the requirements of the metals industry.

A central element of TWMS/metals are the rule books in which the specific parameters and restrictions for the transport and storage of the individual items are defined. The rules are formulated taking into account the material properties, customer specifications and production planning requirements.

They are freely parameterizable and restrictions or priorities can be modified and extended at any time as desired.

Rules may read as follows: “IF an item is to be dispatched during the next few hours, THEN it will be stored near the closest loading station.”

During the installation of the system in the mill environment, the practice-proven core modules are adapted to the specific local conditions or expanded as desired. Whether rolling mills or finishing areas, slabs or coils, cranes or coil ferries – these and many more elements are already pre-installed in the system ready to be configured for the task on hand.

TWMS/metals is easily adaptable: We know that operations in mills are subject to frequent change: production processes are constantly improved, storage rules refined, the material flow optimized, a new line started up, or a storage area may become temporarily unavailable. TWMN/metals can be easily adapted to changing conditions via interactive editors with intuitive user guidance so that no external support is required.

What makes storage operations in the slab yard particularly challenging is the fact that a great many parameters need to be observed when stacking slabs. TWMS/metals assigns the storage positions with a view to logistical requirements in order to avoid frequent shifting.

Additionally, it is crucial that the slabs are stacked on one another with utmost precision. Therefore, a key feature of TWMS/metals is its ability to trace the crane positions extremely accurately.

In cases where the standard tracing function is not sufficient - for example, when handling narrow slabs or billets - we use additional information such as the surface profile of the slab stack.

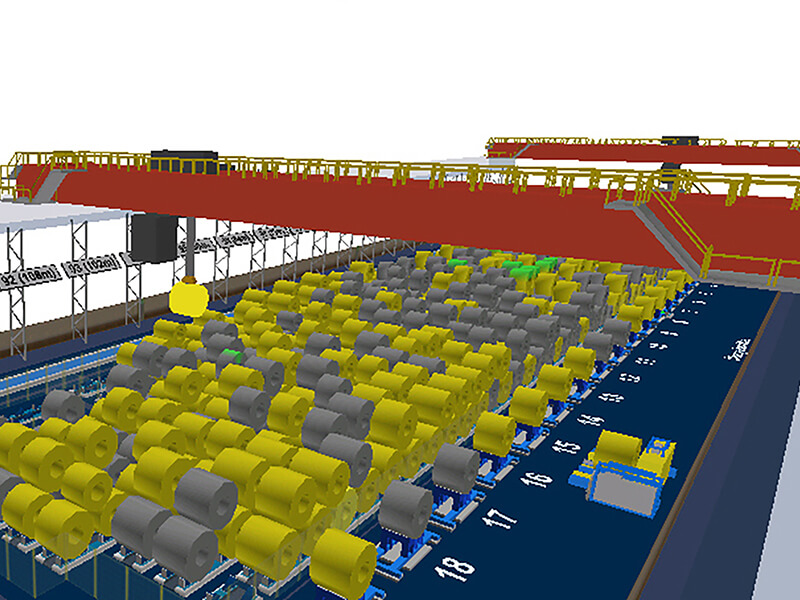

The optimal storage position of a coil depends on a number of aspects, for example, on the available space, the structural and mechanical parameters of the coil rack and on whether the properties of the coils already in the rack would allow another coil to be placed on top of them.

In order to find the most suitable storage position for a coil, TWMS/metals in each case calculates the force vectors that would act on the coil racks. This guarantees that storage of a coil in the desired position will always be safe and stable.

TWMS/metals supports all transport equipment typically in use in a coil yard, for example:

- Cranes

- Coil lifting trucks

- Coil ferries

- Chain conveyors

- etc.

We acquire the current position of the transport equipment by different systems to best suit the situation, for example, by means of radar or by laser sensors.

In steel service centers the variety of products is of course greater and the lot sizes smaller than in rolling mills. But thanks to its scalable architecture, TWMS/metals can also reliably handle such conditions

What makes the situation in a plate mill challenging is the fact that the stacks of stored plates consist of many more layers than, for example, the stacks in a slab yard. The plates vary in length and sometimes two cranes may be needed to lift and transport them. In these cases perfectly synchronous operation of the two cranes must be guaranteed.

Usually, the plates are lifted by way of magnets. TWMS/metals performs plausibility checks to guarantee that always the correct number of plates are lifted.

3tn has developed a special HMI for crane operators, which allows them to zoom in on the selected stack in a virtual environment and see at a glance all relevant data about each individual plate.

Further information.

We are happy to advise you.

Further information.

We are happy to advise you.