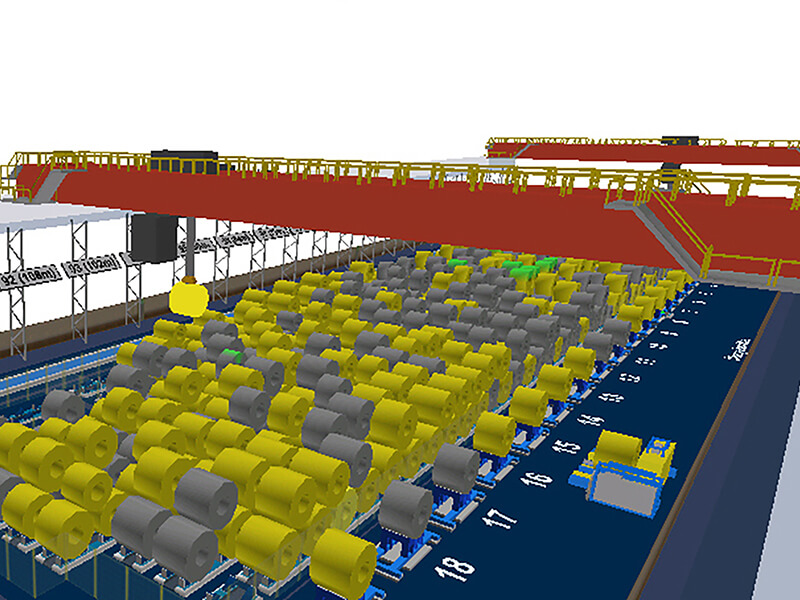

Taking into account the number and type of items to be transported and the current storage situation, TWMS/metals determines the optimal storage places within individual production shops or across complete works, and generates the pertaining transport orders fully automatically.

Apart from the current situation in the storage areas, it considers priorities and restrictions such as:

- Which item is to be stored where?

- Is the storage location adequate for the specific item?

- May an item be stacked on top of another one?

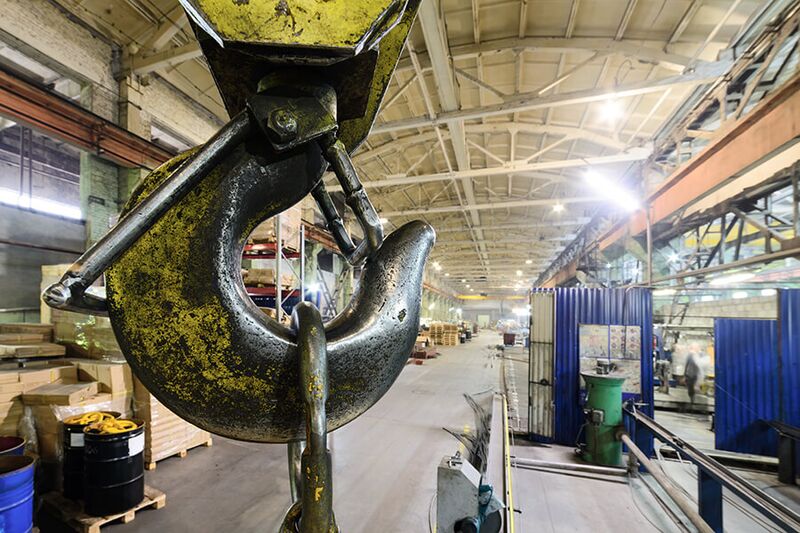

TWMS/metals plans the routes, taking into account incidents such as temporary blocking of transport equipment or of transport routes.

In the one direction, it communicates with ERP and MES systems and, in the other, with the basic automation system and data from the sensors.

If used with tablet PCs or hand-held terminals, TWMS/metals becomes mobile and suitable for use by crane and vehicle operators.