The function

What TWMS/metals achieves.

When an item – for example, a slab or a coil – is to be transported to a storage place, TWMS/metals receives the corresponding information from the production control system or the MES or ERP systems, or it generates the information autonomously on the basis of internal rule books.

TWMS/metals determines the optimal storage place, the best suited combination of the transport equipment and the best route to the storage place. In doing so, it takes into account the current inventory situation, the availability of resources and the rule books which may have supportive or restrictive effects on the transport and storage operations.

Then TWMS/metals triggers the orders for the vehicle operators and for the automated transport equipment, e.g. cranes or coil ferries. Upon completion of a transport order, the system sends a “complete” message to the higher-lever systems.

TWMS/metals can also be configured to manage the complete dispatch of the products. This may include the issuing of the delivery notes, the assignment of the products for shipment by truck or wagon, the consignment and optimal loading of the goods.

Operation

From our extensive project experience we know that it is essential to always bear in mind the operators’ needs.

We place greatest emphasis on creating an HMI that supports the human operator as best as possible. In all our projects we give highest priority to user-friendliness and clearly structured, realistic visualization.

Use of our software is highly intuitive. User guidance via context-sensitive menus and touch screens facilitates operation, also for users new to the system. The system is well accepted by the operators – a key requirement for the success of your project.

The HMI is available in different languages and customizable to the specific terminology of the mill.

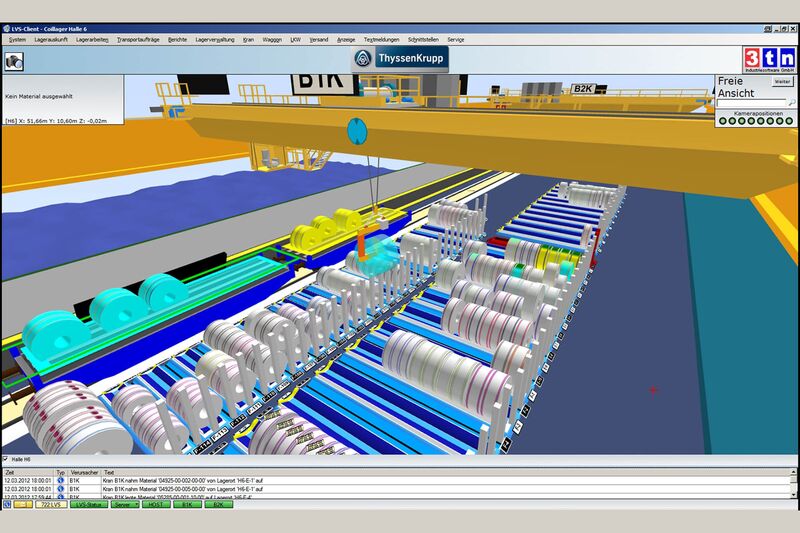

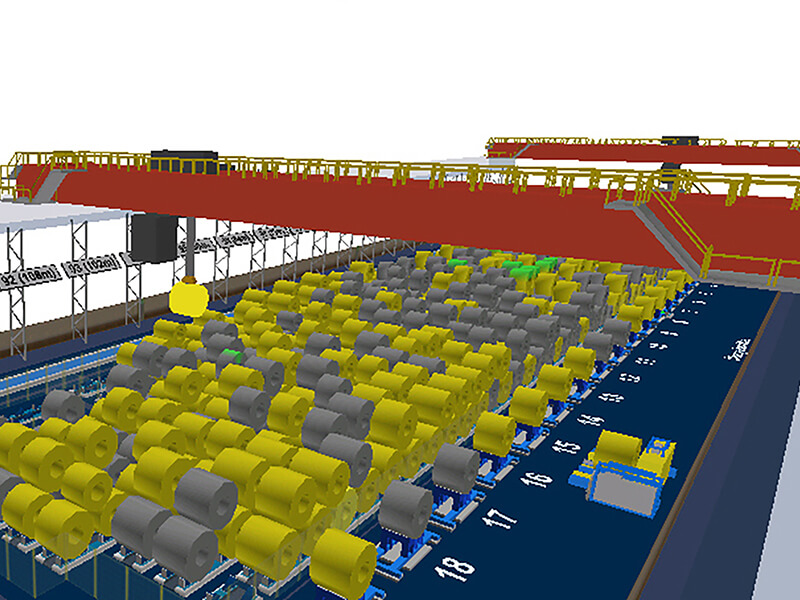

TWMS/metals generates realistic interactive and real-time 3D displays of the storage situation. The viewing positions and angles can be freely selected. In addition to the current status of the storage area, other useful information is displayed. For example, the operator sees at a glance whether a coil is blocked, whether a certain slab would be suitable for storage in a particular position or whether that would possibly violate a restriction.

With a mouse click additional information can be retrieved, for example, ID numbers and material data, or any existing blocking notices.

On a display in the crane cabins, the operators see the storage situation from their current position and perspective. They are guided by arrows from one position to the next, while seeing all information they need for processing the order on hand.

In all displays, the coils are shown complete with related information, e.g. the coil Ident, and they are highlighted in different colors indicating whether they have to be loaded on a truck or wagon, or whether they have been blocked.

A three-dimensional view is implemented at the client terminals in the offices of the quality assurance personnel and the production managers. The users may freely move about the display and view the storage situation in the plant from any perspective. If they wish to see the exact position of a coil, they can zoom in on it from the total view.

FAQ Frequently Asked Questions

Storing slabs, coils and plates as efficiently as possible has always been a challenging endeavor in the steel and aluminum industries.

Product storage and handling are much more complicated than in other sectors or, for example, in high-bay stores. Slabs and coils – often of different sizes – have to be stacked on top of each other. This requires numerous parameters to be observed, for instance, the condition of the product surface and the product weights, all of which determine the forces acting on the stored items and on the equipment and the sinking depths.

Additionally, various restrictions have to be taken into account in order to find the best suited storage position for each individual stored product.

We have developed TWMS/metals specifically for the requirements of the metals industry.

A central element of TWMS/metals are the rule books in which the specific parameters and restrictions for the transport and storage of the individual items are defined. The rules are formulated taking into account the material properties, customer specifications and production planning requirements.

They are freely parameterizable and restrictions or priorities can be modified and extended at any time as desired.

Rules may read as follows: “IF an item is to be dispatched during the next few hours, THEN it will be stored near the closest loading station.”

During the installation of the system in the mill environment, the practice-proven core modules are adapted to the specific local conditions or expanded as desired. Whether rolling mills or finishing areas, slabs or coils, cranes or coil ferries – these and many more elements are already pre-installed in the system ready to be configured for the task on hand.

TWMS/metals is easily adaptable: We know that operations in mills are subject to frequent change: production processes are constantly improved, storage rules refined, the material flow optimized, a new line started up, or a storage area may become temporarily unavailable. TWMN/metals can be easily adapted to changing conditions via interactive editors with intuitive user guidance so that no external support is required.

What makes storage operations in the slab yard particularly challenging is the fact that a great many parameters need to be observed when stacking slabs. TWMS/metals assigns the storage positions with a view to logistical requirements in order to avoid frequent shifting.

Additionally, it is crucial that the slabs are stacked on one another with utmost precision. Therefore, a key feature of TWMS/metals is its ability to trace the crane positions extremely accurately.

In cases where the standard tracing function is not sufficient - for example, when handling narrow slabs or billets - we use additional information such as the surface profile of the slab stack.

The optimal storage position of a coil depends on a number of aspects, for example, on the available space, the structural and mechanical parameters of the coil rack and on whether the properties of the coils already in the rack would allow another coil to be placed on top of them.

In order to find the most suitable storage position for a coil, TWMS/metals in each case calculates the force vectors that would act on the coil racks. This guarantees that storage of a coil in the desired position will always be safe and stable.

TWMS/metals supports all transport equipment typically in use in a coil yard, for example:

- Cranes

- Coil lifting trucks

- Coil ferries

- Chain conveyors

- etc.

We acquire the current position of the transport equipment by different systems to best suit the situation, for example, by means of radar or by laser sensors.

In steel service centers the variety of products is of course greater and the lot sizes smaller than in rolling mills. But thanks to its scalable architecture, TWMS/metals can also reliably handle such conditions

What makes the situation in a plate mill challenging is the fact that the stacks of stored plates consist of many more layers than, for example, the stacks in a slab yard. The plates vary in length and sometimes two cranes may be needed to lift and transport them. In these cases perfectly synchronous operation of the two cranes must be guaranteed.

Usually, the plates are lifted by way of magnets. TWMS/metals performs plausibility checks to guarantee that always the correct number of plates are lifted.

3tn has developed a special HMI for crane operators, which allows them to zoom in on the selected stack in a virtual environment and see at a glance all relevant data about each individual plate.

Rule books

A central element of TWMS/metals are the rule books in which the specific parameters and restrictions for the transport and storage of the individual items are defined.

The rules are formulated taking into account the material properties, customer specifications and production planning requirements.

They are freely parameterizable and restrictions or priorities can be modified and extended at any time as desired.

Rules may read as follows:

- “IF an item is to be dispatched during the next few hours, THEN it will be stored near the closest loading station.”

- “IF an item exceeds a certain temperature, THEN it will not be placed near an aisle.”

- “IF an item has top priority in the production sequence, THEN the transport priority of the item will be automatically raised.”

During the installation of the system in the mill environment, the practice-proven core modules are adapted to the specific local conditions or expanded as desired. Whether rolling mills or finishing areas, slabs or coils, cranes or coil ferries – these and many more elements are already pre-installed in the system ready to be configured for the task on hand.

TWMS/metals is easily adaptable: We know that operations in mills are subject to frequent change: production processes are constantly improved, storage rules refined, the material flow optimized, a new line started up, or a storage area may become temporarily unavailable. TWMN/metals can be easily adapted to changing conditions via interactive editors with intuitive user guidance so that no external support is required.

The user can enter new rules during running operation (“at runtime”) without affecting the overall availability of the system.

Reporting

The report generator is a graphical user tool by means of which reports, lists, etc. can be freely generated from any of the data available in the system.

In order to make the reports generally accessible for the operators, they can be integrated into the user menus as an option. Reports can also be sent automatically to designated users at defined times. For example, a shift report may be sent out every morning at a specified time.

Further information.

We are happy to advise you.

Further information.

We are happy to advise you.